A short history of geomechanics in Schlumberger

The oil and gas industry considers geomechanics, the theoretical and applied science of the mechanical behavior of geological material, to be a young and niche discipline associated with the rise of shale oil fracking in the United States. However, under the more limited discipline of rock mechanics used in mining and civil engineering, geomechanical principles have been applied to underground mining, slope stability, railroad and automobile tunnels, and dam placement since the end of the 19th century. Failure assessment of disasters such as the St. Francis Dam (USA, 1928) and Vajont Dam (Italy, 1963) led engineers to understand the significance of geomechanical considerations on a large scale. In the petroleum industry geomechanical principles were first applied in a "rule of thumb" approach in the late 1950s with the development of hydraulic fracturing to enhance oil production from mature oil fields.

Schlumberger entered the geomechanical discipline with both feet, after the development of its new sonic logging tool in the early 1970s. Log analysts discovered they could use one of the waves the sonic tool measured, compressional slowness (DT), as a proxy for reservoir strength and use it to predict sanding propensity (the point where the reservoir formation breaks down and sand clogs the wellbore). The "mechanical property log" (SPE-4532-PA) was born and became part of first log analysis software package from Schlumberger, Saraband.

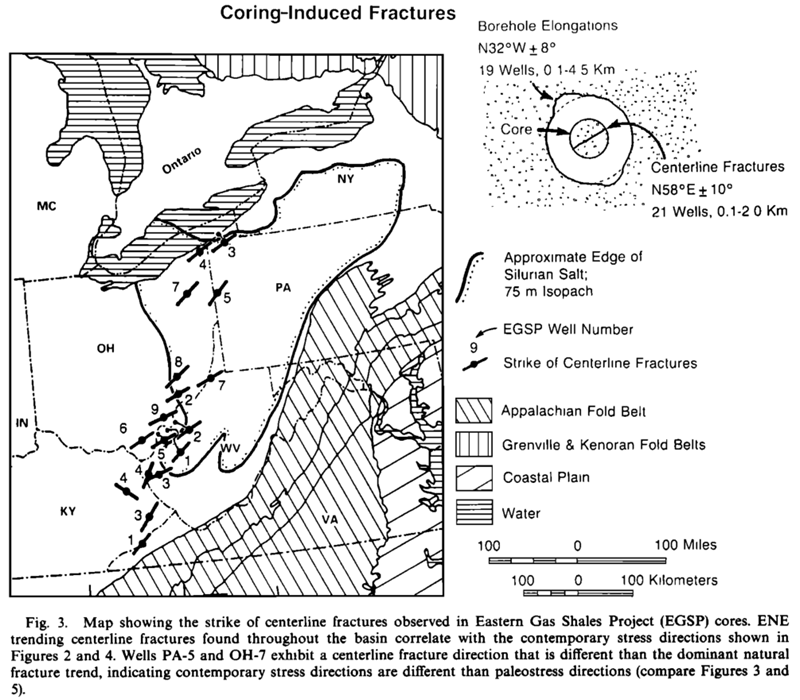

Schlumberger’s success in hydraulic fracturing in the US continued to lead geomechanical development through the 1980s with the development of new tools such as the FST (later to become FMI) and the dipole sonic tool (DSI). Measurements from these tools enabled Schlumberger scientists to calculate such vitally important information as fracture gradients, dynamic elastic properties, and stress directions that can affect wellbore stability.

Geomechanical log analysis became an integral part of log processing software from Schlumberger and its interpretation business. MecPro was the first full geomechanics module in GeoFrame, and we still use a MecPro correlation in today's software. The October 1986 issue of The Technical Review was dedicated to rock mechanics covering topics such as; estimating earth stresses at depth, determining formation sanding potential, using geomechanical models to predict the dimensions of hydraulic fractures and theory of fracture mechanics and wellbore stability.

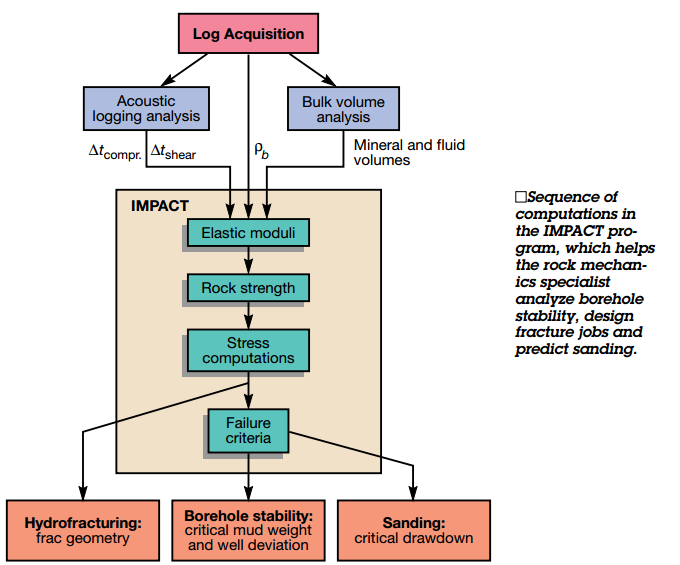

In the early 1990s, scientists at the Schlumberger Cambridge Research lab worked with BP on drilling problems in the Columbia oil field, Cusiana. This study became the first wellbore stability consulting project and introduced the term mechanical earth model (MEM). The workflow developed in this study became the GeoFrame module IMPACT. Any user of the geomechanics tab in the Techlog wellbore software platfrom will recognize this workflow:

In 1997 the success of the Cusiana WBS study led to the creation of geomechanics consulting teams in Houston and London. The first commercial services offered by these teams, and other engineers worldwide, include the ‘No Drilling Surprises’ solution and the PERFORM drilling optimization service. These were the first of many real-time geomechanical, drilling support incarnations.

A significant milestone for our geomechanics software development occurred in 2007 with the acquisition of a consulting and software company, V.I.P.S., founded in the UK and the originator of the reservoir geomechanics simulator, VISAGE finite-element geomechanics simulator. Over the following years, the VISAGE simulator integrated with the Petrel E&P software platform and the consulting team of V.I.P.S. became what is today the "Geomechanics Centre of Excellence" at Gatwick, UK. Today, this team pushes the limits of numerical geomechanics simulation, for example extending coupled geomechanics simulation into the realm of geological forward modeling.

The second wave of hydraulic fracturing, shale oil, exploded while reservoir geomechanics became an integral part of conventional oil and gas exploration and development. Schlumberger developed another new logging tool, the SonicScanner acoustic scanning platform, to focus on geomechanical applications. The commercialization of the SonicScanner platform in 2005 increased our understanding of acoustic anisotropy (the non-uniform way sound travels through geologic materials) and is a critical tool for understanding stress, elastic properties, and hydraulic fracturing success. It remains the wireline workhorse for geomechanics engineers in Schlumberger and leading to many effective analytic algorithms and software modules in the Techlog platform for acoustic and elastic anisotropy.

Geomechanics engineers are found primarily in the geomechanics software and services business. They also play an essential role in other Schlumberger business lines: geomechanics and acoustics domain champions in Wireline and D&M, pore pressure analysts in Geoservices and pore pressure modellers in WesternGeco, geomechanics researchers at the Schlumberger Doll Research Center in Boston, MA, the specialists in our rock mechanics laboratories of TerraTek in Houston and Abu Dhabi, and many others.

Geomechanics has been an integral part of Schlumberger business going back to the 1970s and an early boom in hydraulic fracturing. It has grown over the years to include many different types of studies, measurements, and modeling tools.

Author information: “Geomechanicist: professional translating geology into engineering language." In university, I translated geology into geologic engineering predictions for tunnel projects; after joining Schlumberger as a scientist in the Cambridge Research Center, I translated geology into drilling and completions engineering predictions. A tunnel is a large, horizontal wellbore. Thus, along with many older geomechanics engineers in the oil and gas industry, I am comfortable in both the civil engineering and drilling engineering world. Looking back to over three decades of rock mechanics work, I realize I have an affinity for explosives. When doing fieldwork for my masters’ thesis in a small Austrian village, I enjoyed a short period of fame as, “The girl who sits on a box of explosives while mapping the tunnel face.” Twenty years later, I worked for three years in the Schlumberger perforating lab, analyzing the mechanical impact of shaped charge explosions on rocks. Since 2015, I spend most of my time teaching geomechanics for NExT and our internal training program in Schlumberger. As the "domain career manager" for geomechanics, I work to create a thriving geomechanics community and help all geomechanics engineers in Schlumberger perform their best.